The methodology uses a set of statistical tools and techniques, including statistical process control, design of experiments, and regression analysis, among others. Six Sigma projects are typically carried out by trained professionals known as “Black Belts” and “Green Belts,” who lead teams through the different phases of the Six Sigma methodology.

Overall, Six Sigma aims to reduce variation, increase process efficiency, and enhance the quality of outputs, leading to improved customer satisfaction and business performance.

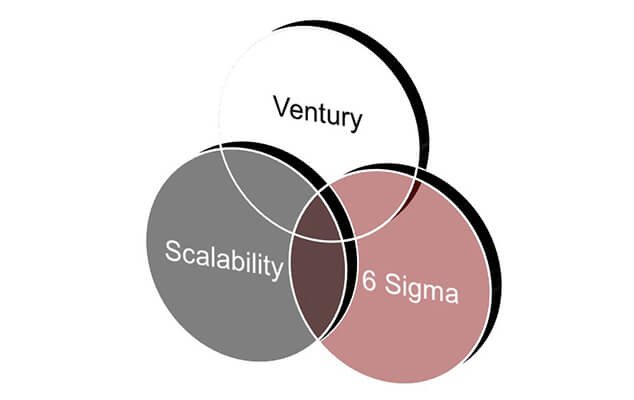

Lean Six Sigma is a methodology that combines two powerful process improvement techniques: Lean and Six Sigma.

Lean focuses on minimizing waste and maximizing efficiency by identifying and eliminating non-value-adding activities. This involves streamlining processes, reducing defects, improving quality, and optimizing resources to deliver more value with less effort.

On the other hand, Six Sigma is a statistical approach to process improvement that aims to reduce variation and defects by using data-driven decision making. It involves defining, measuring, analyzing, improving, and controlling processes to achieve consistent and predictable results.

By combining the strengths of these two methodologies, Lean Six Sigma provides a comprehensive approach to process improvement that can be applied to any industry or sector. It is widely used in manufacturing, healthcare, finance, and service industries to improve efficiency, reduce costs, and enhance customer satisfaction.

This is based on the popular belief that the “customer is the king.” The primary goal is to bring maximum benefit to the customer. For this, a business needs to understand its customers, their needs, and what drives sales or loyalty. This requires establishing the standard of quality as defined by what the customer or market demands.

DMAIC is a data-driven method used to improve existing products or services for better customer satisfaction. It is the acronym for the five phases: D – Define, M – Measure, A – Analyse, I – Improve, C – Control. DMAIC is applied in the manufacturing of a product or delivery of a service.

DMADV is a part of the Design for Six Sigma (DFSS) process used to design or re-design different processes of product manufacturing or service delivery. The five phases of DMADV are: D – Define, M – Measure, A – Analyse, D – Design, V – Validate. DMADV is employed when existing processes do not meet customer conditions, even after optimization, or when it is required to develop new methods