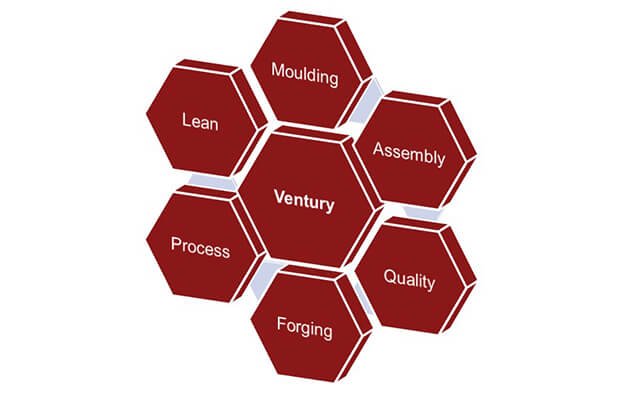

At Ventury Engineering, our unwavering commitment to excellence is reflected in a comprehensive array of capabilities that redefine the benchmarks of modern manufacturing. With a perfect fusion of cutting-edge technology and seasoned expertise, we stand at the forefront of the industry, offering tailored solutions that meet the diverse needs of our clients.

At the heart of our capabilities lies the artistry of injection moulding. We specialize in transforming raw materials into intricate and precisely crafted components. Our advanced injection moulding processes not only allow us to achieve complex designs but also ensure consistency in every product. The precision inherent in our moulding techniques sets the stage for unparalleled quality.

In the pursuit of manufacturing perfection, precision and consistency are non-negotiable. Our commitment to these core values defines every aspect of our operations. Through rigorous quality control measures and a meticulous approach to production, we guarantee that each product leaving our facilities adheres to the highest standards of precision and consistency.

Understanding the nuances of materials is a hallmark of our expertise. We work closely with our clients to navigate the intricate landscape of material selection, ensuring that each component is crafted with the optimal material for its intended purpose. Whether it’s durability, flexibility, or aesthetic considerations, our material selection process is a testament to our commitment to delivering tailored solutions.

The journey to excellence begins with meticulous mould design. Our team of skilled engineers collaborates to create innovative moulds that not only meet but exceed expectations. The commitment doesn’t end there; our proactive mould maintenance programs ensure the longevity of our tools, minimizing downtime and maximizing efficiency in the production process.

Quality is not just a goal; it’s a continuous journey. Our state-of-the-art process monitoring and control systems scrutinize every step of our manufacturing process in real-time. This vigilance allows us to identify and rectify deviations promptly, ensuring that each product maintains the highest quality standards throughout production.

Precision begins with the machines we use. Regular calibration of our injection moulding machines is a testament to our commitment to optimal performance. This meticulous approach not only enhances efficiency but also contributes to the reliability and longevity of our equipment, ensuring seamless production runs.

Beyond injection moulding, our capabilities extend to the realms of casting and forging. This versatility positions us as a comprehensive manufacturing partner, capable of delivering solutions across a spectrum of project requirements. Our expertise in these traditional methods complements our modern approach, offering clients a holistic manufacturing experience.

In conclusion, our capabilities at Ventury Engineering are a symphony of precision, consistency, and versatility. With a focus on innovation and a commitment to exceeding expectations, we stand as pioneers in the ever-evolving landscape of modern manufacturing